5 facilities management tactics to cut manufacturing costs

Create more value from your space with efficient processes and cutting-edge technology

Manufacturing companies have always faced pressure to operate facilities efficiently, but the need to contain costs has recently taken on a new dimension for facilities management (FM) teams. Corporate sustainability mandates, labor shortages, supply chain disruptions, and shifting market forces have added new layers of complexity to keeping costs in check.

Luckily, many strategies companies can use to save money can also tackle these other challenges, such as improving energy efficiency and bridging workforce skills gaps. Manufacturers can turn headaches into advantages by harnessing the power of data, cutting-edge technology, automation, and continuous process improvement.

How can companies use these tools to drive efficiencies throughout their facilities?

Five best practices for profitable manufacturing facilities management

The following strategies can help your team reduce operating costs and boost efficiency and bottom lines while maintaining reliability and supporting other facility goals:

1. Build a shared vision and align on outcomes

Effective FM starts with the end in mind. When your entire team is aligned around a common purpose, they can work together more effectively to achieve the desired outcomes. For facility managers in manufacturing, that means delivering high-performance environments that optimize production and are healthy, safe, secure, resilient, reliable, and compliant—all while protecting asset value and running operations at peak efficiency –no easy feat.

But first, you need a finely tuned strategy. Define the key performance indicators that will measure success. Map out the roadmap to guide your team in hitting each milestone. Then, let the data shine, tracking progress and singling out areas for improvement. By focusing on desired outcomes rather than checklists of activities, FM teams are more likely to invest in innovative ideas and tools to maximize financial performance.

2. Streamline processes with technology

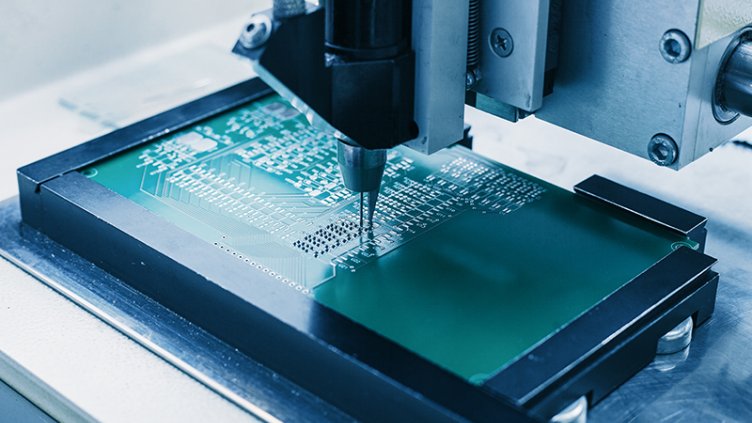

In today’s challenging labor landscape, smart investments in technology can help bridge gaps in worker availability and skills. For example, some companies use artificial intelligence (AI), as well as augmented and virtual reality devices or digital twin technology, which enable experienced technicians to help troubleshoot equipment issues remotely.

Cleaning and landscaping robots and sensor technologies can also boost efficiency. For example, in manufacturing facilities with clean rooms, such as semiconductor plants, FM teams must suit up every time they service the room, which can take 15-20 precious minutes multiple times a day. Proximity sensors can alert the FM team when service is needed — such as when waste bins are getting full — so they don’t have to enter the clean room as frequently.

3. Aggregate data for better decision-making

The digital transformation and smart building revolution has arrived, arming facility managers with a new tactical arsenal of efficiency -- and data is the ammunition. It starts by centralizing all facility data into a single, easily digestible platform so they can view all energy usage, equipment vitals, and operational activities at a glance.

JLL Serve, an end-to-end digital FM application, is one of these powerful lenses. It uses AI to integrate data from connected and non-connected assets into one interface. Systems like these give facility managers everything they need to do their jobs efficiently in one place.

4. Embrace reliability-centered maintenance

In traditional maintenance programs, technicians service and replace equipment based on frequency-based schedules set by equipment manufacturers or corporate standards. However, this calendar-based approach is suboptimal, often leading to low value redundant tasks or unnecessary capital expenditures. Sometimes, equipment is replaced before the end of its useful life. Other times, it may require emergency maintenance because parts wear out ahead of schedule.

In contrast, reliability-centered maintenance (RCM) helps FM teams determine the best approach for each asset based on its criticality. For example, technicians can use tools like infrared thermography or vibration analysis to monitor equipment that requires 100% uptime in real time. For non-critical, easy-to-replace equipment, letting the asset run to failure may make more sense. RCM allows FM teams to prioritize reliability at the lowest cost.

5. Integrate processes inside and outside the yellow line

Manufacturing facilities typically have separate teams and processes to manage spaces outside and inside the yellow line — where production happens. While having separate teams serves an important purpose, integrating processes, technologies and data across that boundary can help create efficiencies.

A coordinated approach can unearth massive efficiency gains, especially when investing in innovative technologies. An AI-driven inventory management system, for example, is exponentially more powerful when used by both FM and the team managing production line equipment.

Get more value from your manufacturing facility management

Manufacturing FM teams face many challenges today, but that needn’t get in the way of cost savings. By aligning your team around strategic outcomes and incorporating data and technology, you can run safe, reliable and sustainable facilities while staying within budget.

Want to get the most from your manufacturing facilities? Contact JLL today.